The key to success

Digital technology and the world of construction By Jim Stephen

As construction jobs grow increasingly complex, companies strive to find new ways to increase productivity without creating unsafe working conditions or going woefully over budget. Digital technology presents an opportunity to change the way construction companies work and grants the power to adapt to the industry’s changing landscape.

Digital technology tools for the construction industry

In today’s tech-savvy world, there are hundreds, if not thousands, of digital technology tools available to support businesses with productivity, communication, and more. General software can help teams refine various stages of their workflow and client interactions, but can only take things so far.

To leverage the power of digital technology, firms should use tools designed for the construction industry, like BIM Collaborate Pro. Choosing products that integrate with existing tools and focused on construction-oriented tasks makes the transition easier and leads to better long-term gains.

For example, consider a Customer Relationship Management (CRM) system with the ability to use cloud-based storage and track various metrics, like employee time. It could improve project management and offer some boosts in productivity. However, a general CRM leaves out a large part of construction needs, like accessing and editing plans and models or calculating supply needs and costs.

Conversely, software created specifically for construction teams often features these key elements. It’s not easy to optimize productivity if you can’t perform all the necessary tasks through one platform.

Key ways digital technology can improve the construction industry

Key ways digital technology can improve the construction industry

Knowing that tools exist is one thing, but understanding how they can help a construction business grow is something else. These tools represent an investment in the business, and that means understanding the short and long-term benefits.

Increase productivity

According to a 2021 study, around 60 percent of contractors report delays on projects. Those delays often translate to going over budget and failing to finish on time. In fact, only half of all projects finish on time and on budget.

Digital technology could be the solution to these costly delays. The right software can help teams create a smoother workflow and house all relevant information in one place.

A cloud-based platform can make it accessible from anywhere, meaning on-site workers can see the same thing as those at the head office.

Additionally, platforms can track updates, changes, and daily progress to make appropriate adjustments. It’s possible to refine scheduling needs or reallocate resources to adapt to changes faster and more efficiently.

More efficient communications

Imagine a world where teams can craft a design, perfectly scaled to match a specific site. The team can then share the model with their clients and make real-time corrections. What could that possibility mean for the company and the client?

Digital technology can help teams limit the back and forth by providing accurate displays with real-time editing capabilities. It reduces the chance of miscommunications and misinterpretations as all parties can simultaneously view the same model from almost anywhere.

These tools can bridge gaps between time zones and worksites to create more efficient, open communication and reduce one of the most common issues with any construction project. It’s possible to create transparency between teams, crews, and clients.

Reduce errors and waste

As noted, finishing a project over budget remains a significant problem. Embracing digital technology could be the best way to reduce costly errors and wasted resources.

Choosing software and hardware built for the construction industry means accessing powerful analytics to solve problems before the work even begins. For example, creating the project in the virtual system allows teams to work through potential issues, get more accurate measurements, and deliver more accurate numbers to clients.

When teams can construct a virtual image of the project in various modes, it’s easier to pinpoint potential problems. Additionally, using Artificial Intelligence (AI), it’s possible to get more accurate measurements and calculations for the project. Leveraging AI for calculations and predictions can reduce the impact of human error and reduce waste on the project.

Track work efficiently

Another area with room for improvement is crew member management. Digital technology improves workflow and streamlines scheduling to reduce employee downtime and overages. Instead of having crew members standing around on the clock with nothing to do, it might be possible to shift them to other sites to maximize efficiency.

Incorporating time-tracking apps within the software package also makes it easier to record progress, handle any discrepancies, and manage multiple crews. It can even include GPS location abilities to ensure teams are on track and at the proper locations.

When management, payroll, human resources, supervisors, and crew members can all access the same information, it’s easier to monitor individual employee performance. Again, it creates more transparency and open communication with fewer discrepancies and less room for error.

Create safer worksites

Create safer worksites

Embracing digital technology involves more than software with AI, analytics, and tracking abilities. It represents a way to improve worksite safety and reduce strain on employees.

Improve training and compliance

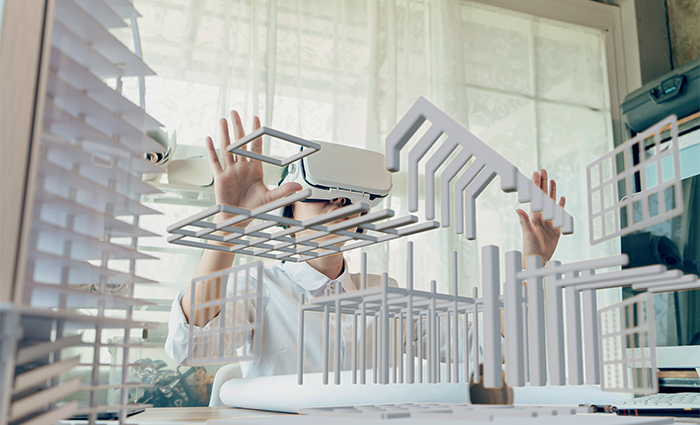

Technology allows employees to use alternative training methods, like VR and 3D models to simulate real-life scenarios. It’s more effective than reading information and warnings out of a manual.

Speaking of manuals, instead of maintaining massive paper binders and manuals on sites, digitize records. It’s simpler for tracking and allows teams to complete reports through mobile devices, including safety measures.

Monitor sites with drones

It’s not easy for team leads to monitor an entire site, but a drone can help. Flying drones over sites allows supervisors to see what’s happening, keep tabs on site conditions, and spot any safety issues.

Wearable devices

Wearable devices represent another way to leverage technology to improve safety on worksites. Smartwatches and smart clothing can track various metrics and alert management to dangerous situations, like dehydration or toxins in the air. Additionally, with GPS features, it’s possible to locate injured crew members faster.

Embracing digital technology in the construction industry

Digital technology represents the present and future of the construction industry. It’s the best way to increase productivity, reduce costs, limit errors, and keep projects on track. Investing in a construction-focused, cloud-based platform could be the key to future success and continued growth.

For a list of the sources used in this article, please contact the editor.

Jim Stephen

www.microsolresources.com

Jim Stephen is an Account Executive for Construction Solutions at Microsol Resources based in New York. Microsol Resources is a recognized leader with the best software tools for architectural design, engineering, and the construction industry.