The science of strategic equipment maintenance schedules in harsh environments

Nothing quite wastes crucial time like downtime in the construction industry. Ensuring your equipment and team are prepared to maximize uptime can help prevent potential operational hazards and delays, especially in inclement weather. In North America, Warren CAT is a trusted construction equipment partner serving Oklahoma, West Texas and the Texas Panhandle.

From natural disasters to unprepared equipment, losing valuable time during a project can be costly. Learning essential heavy equipment downtime prevention strategies helps create a more efficient, cost-effective daily workflow. Warren CAT recognizes this problem, which is why it aims to target potential barriers that result from faulty machinery.

Warren CAT emphasizes responsive field service to help you avoid costly delays and keep your job progress on schedule, and says, “our trained field service technicians work quickly and efficiently to troubleshoot, problem-solve, and perform the repairs or services you need. We get in, make the fix and get back to work.”

Unique Challenges for Equipment

From extreme rain to dust storms, any momentarily passing change in weather can dramatically alter your workflow and equipment. Even sunny days can cause havoc for on-site workers. When it is hot and dry outside, operators and equipment are at risk of needing downtime. Equipment malfunctions can occur due to excessive heat, which, as a result, can require additional maintenance to ensure your Caterpillar equipment functions properly in harsh environments. Additionally, workers are at a higher risk of heat-related illnesses.

However, any significant change in weather conditions can alter the progress of a construction project. To prevent this issue, your staff must undergo the proper safety training before heading out onto the field. You’ll also want to ensure that you and your team can recognize warning signs that a machine is beginning to deteriorate or become hazardous. Overall, it’s essential to take the proper steps to care for your machinery before it reaches its breaking point.

Managing the longevity of your equipment is a big part of maximizing uptime. However, it is not the only crucial element to consider. To ensure you can depend on your team, make sure all workers can rely on you or other managers. Effective communication can ensure that machinery is used as needed and the workflow proceeds smoothly.

While your team can keep a watchful eye out for damaged equipment, it is more efficient to anticipate incidents or replacement needs ahead of time. Incorporating high-tech solutions that aim to boost productivity and eliminate risk. Warren CAT offers many solutions for this. Consider investing in trustworthy technology and highly dependable Caterpillar products that increase productivity and monitor operational data/workflow.

The True Cost of Downtime: Beyond the Obvious

Unplanned moments of downtime can present numerous costly issues, including delays in project completion, which can impact other future jobs.

The upfront costs of extending projects will be the least of your worries if you consider the additional expenses of expedited parts with higher shipping costs, on-site services, and extended rental agreements. Overall, this could result in a more rushed project, which can have a lasting impact on your reputation.

Additionally, hasty work can lead to an incident. In 2023, reports showed that the construction industry had one of the highest numbers of fatal work incidents in the United States. Rushed jobs, poor communication, and faulty equipment can put workers at a greater risk of injury.

Reduce these stressors by taking an active role in implementing the right preventive measures for construction equipment. Thoughtful consideration of servicing equipment is one of the most important ways to ensure you are maximizing uptime without fail.

Taking an Active Role in Preventative Care

The operational workflow can be performed more effectively if your machinery is considered. Equipment issues can be a hassle because of the need to complete a project. If an error should occur, you’ll have to pause a project to order new parts, rent new machinery or seek repairs. Aim to create a maintenance schedule for each machine is the most in-depth and trustworthy solution. The process of knowing if your equipment needs an update depends on the product.

Maintaining an organized list and staying in communication with highly reputable advisors is essential to this process. Weather, overuse and more can all play a key role in your equipment needing service. Ensure your equipment stays up to date.

Warren CAT is committed to ensuring that your needs are met and optimizing your daily workflow to maximize efficiency.

Warren CAT writes, “from standard preventative maintenance to complete rebuilds and repairs of complex components, we have the broad capabilities and unmatched expertise required to meet your expectations for professional service.” Overall, Warren CAT commits to providing its customers with dependable and long-lasting service.

Don’t just assume all your machines will work just because you don’t see any apparent scratches or dents. Take the time to develop a strategic outline for the services needed.

Take control of your jobsites by initiating proper preventative maintenance to get ahead of downtime. Maintenance checks shouldn’t be scheduled only after a piece of equipment has become an operational hazard. Your construction equipment should have routine service and maintenance schedules in place.

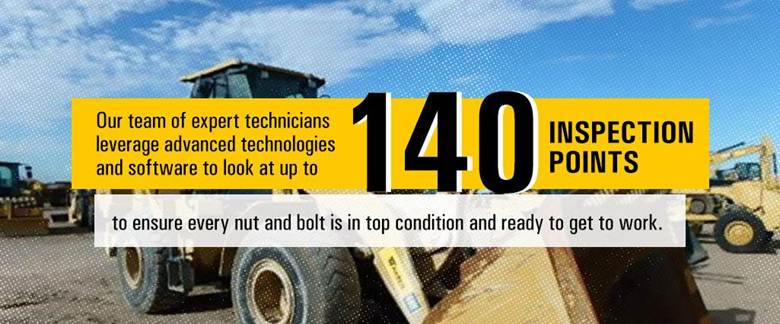

Warren CAT can be relied on for scheduled equipment inspections to ensure quality maintenance checks. By maintaining updated records of inspection expectations for dependable and high-quality equipment, Warren CAT has earned its reputation as an expert company that you can trust. Regular service inspections remove doubt from your daily workload. Don’t just wait around for an incident to occur. Create a service plan that is feasible and prevents downtime.

Conclusion and Actionable Takeaways

Constant downtime is a common yet inefficient approach to any construction project. Since planning for incidents or weather can present its own challenges, consider scheduling preventative maintenance for your construction equipment. Warren CAT’s leading insights are crucial for dependable heavy construction equipment care within Oklahoma, West Texas and the Texas Panhandle. Speak with a Warren CAT professional about setting up routine preventative maintenance checks to maximize your uptime.